Tandem trailer PT510, PT512

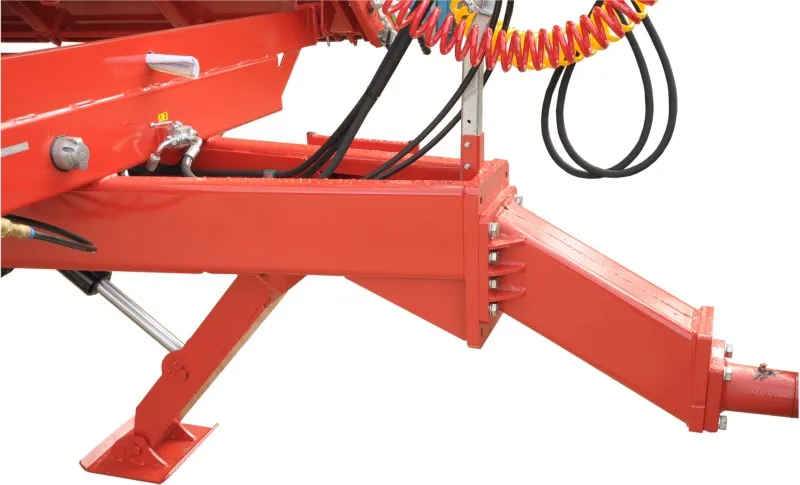

Pronar PT510 and PT512 trailers are excellent solutions, appreciated not only in agriculture, but also in other industries. They are equipped with a sturdy chassis frame made of rectangular closed profiles with a three-way tipping mechanism, a reinforced drawbar, hydraulic scissor support, parabolic springs and strong radial tires.The internal width of the trailer (2420 mm) allows the transport of bulk materials, Euro pallets and box pallets . The trailers are generously equipped with wheel chocks with pockets, rear wheel fenders, service support for the cargo box, ladder and side steps for easy access to the cargo box, and rear outlets (hydraulics and brakes) for a second trailer .Tractor hitch loading facilitates maneuvering in difficult terrain and increases the pulling power of the tractor . The widely spaced wheels ensure the stability of the trailers . A three-way tipping mechanism with a shut-off valve (which activates during side tipping) and a telescopic cylinder ensure the functionality of the trailers .

Ask about the productTechnical data

-

Technical data

Technically (structurally) permissible total weight [kg]Allowable total weight [kg]Payload [kg]Curb weight [kg]Cargo capacity [m3]Cargo area [m2]Length of cargo box inside [mm]Interior cargo box width [mm]Overall dimensions (length/width/height) [mm]Box wall height [mm]Floor/wall plate thickness [mm]Platform height from the ground [mm]Wheel spacing [mm]SuspensionDrawbar eye load [kg]Tire sizeConstruction speed [km/h]Tipping systemTelescopic cylinder (stroke/oil demand/pressure)Minimum tractor horsepower requirement [hp/kW]Tipping angle of the cargo box (rearward/side) [°]150001420010150405013,211454524206139/2550/2452600+6005/2,512501900parabolic springs1700385/65R22,5 RE40tripartite1700mm/15L/200bar74/54,450/46170001626012000426015,411454524206139/2550/2652600+8005/2,512521900parabolic springs1950385/65R22,5 RE40tripartite1980mm/18L/200bar84/61,750/46

-

Standard equipment - PT510

Cargo box with swinging universal wall opening systemThree-way box tipping system with rear suspension ball joints with optimum spacingTipping direction selection by two pins with protection against mishandlingCargo box adapted to transport EUROPALETS, with reinforced floor plateCentral locking at the floor of the side walls and rear wallWalls with side tension bars: made of high-quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged hingesClosed spaces of wall and header profiles protected by laser weldSide tension strips to reinforce the wallsGrain chute shaft, with locking device, in the rear wallLadder and side steps for easy access to the cargo boxChassis frame welded from high-strength structural steel rectangular closed sectionsTandem suspension on 4 parabolic springs, with compensating wishbones, with a wheelbase of 1325mm, with rigid axles equipped with drum brakes of Ø400×80 mmUniversal rigid drawbar for connecting to the lower or upper hitch of the tractorSwivel drawbar hitch with Ø50mm eye, for connecting to tractor lower hitchHydraulic scissor drawbar support with movable foot and safety hydraulic lockAir braking system single-line or dual-line with manual brake force regulator (with rear output)Parking handbrake with crank handleLighting installation 12V, with rear electrical socket, with LED lights, with hermetic connections, with marker lightsRear lighting lamps with grilles to prevent damageConnection cable, spiral, lighting installationTipping hydraulic system with automatic shut-off valve, limiting tipping (with exit to the rear)Three-way telescopic tipping cylinder with articulated slingCargo box service supportSide tension strips to reinforce the wallsSide tension slats to reinforce the extensionsRear wheel fendersTwo wheel chocks housed in galvanized pocketsPaint system with high corrosion resistance with the use of two-component chemically cured paint materials that give high durability of paint coatings and UV resistanceChassis paint color scheme red RAL3000 PRONARWall painting colors green RAL6010 PRONAR

-

Optional equipment - PT510

Type of drawbar hitch: rigid with Ø40mm eyeType of drawbar hitch: rigid ball K80Extensions : made of high quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged locksSlats / tie-down cords for walls / extensions - choice at ordering stageCenter extensions : made of high quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged locksTwo-wire air brake system with automatic (ALB) brake force regulator (with rear output)Air brake system "Premium" two-wire with automatic (ALB) brake force regulator (with output to the rear)Hydraulic brake systemHydraulic brake system with electric safety valve and three-range brake force regulatorBalconyGutter for the chute shaftPlastic fenders (additional) - in front of the front wheelSide protection (guards )Springs to assist the opening of the side wallsManual rear hitch MH 31H-4Automatic rear hitch AH 31H-4Triangle to distinguish slow-moving vehiclesRear chute on the full width of the trailerDeposited chute left or right over the entire length of the trailer bedFolding chute left + right over the entire length of the trailer bedWindow in the front extension (340×710 ) with grille and PLEXII glassWindow in front extension and front center extension (340×710 )with grille and PLEXI glassRoller tarpaulin with frame with folding center tube and side support tubesTwo grain chute shafts, with interlock, in the rear wallThree grain chute shafts, with interlock, in the rear wallPotato fall shock absorber in the form of suspended rubber belts - 2 sets of 1.8m long each mounted to the extensions ( need to equip the trailer with extensions )

-

Standard equipment - PT512

Cargo box with swinging universal wall opening systemThree-way box tipping system with rear suspension ball joints with optimum spacingTipping direction selection by two pins with protection against mishandlingCargo box adapted to transport EUROPALETS, with reinforced floor plateCentral locking at the floor of the side walls and rear wallWalls with side tension bars: made of high-quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged hingesClosed spaces of wall and header profiles protected by laser weldSide tension strips to reinforce the wallsGrain chute shaft, with locking device, in the rear wallLadder and side steps for easy access to the cargo boxChassis frame welded from high-strength structural steel rectangular closed sectionsTandem suspension on 4 parabolic springs, with compensating wishbones, with a wheelbase of 1325mm, with rigid axles equipped with drum brakes of Ø400×80 mmUniversal rigid drawbar for connecting to the lower or upper hitch of the tractorSwivel drawbar hitch with Ø50mm eye, for connecting to tractor lower hitchHydraulic scissor drawbar support with movable foot and safety hydraulic lockAir braking system single-line or dual-line with manual brake force regulator (with rear output)Parking handbrake with crank handleLighting installation 12V, with rear electrical socket, with LED lights, with hermetic connections, with marker lightsRear lighting lamps with grilles to prevent damageConnection cable, spiral, lighting installationTipping hydraulic system with automatic shut-off valve, limiting tipping (with exit to the rear)Three-way telescopic tipping cylinder with articulated slingCargo box service supportRear outlets ( tipping hydraulics and brakes ) for the second trailerRear wheel fendersTwo wheel chocks housed in galvanized pocketsPaint system with high corrosion resistance using paint materialschemically cured two-component giving high durability of paint coatings and UV resistanceChassis paint color scheme red RAL3000 PRONARWall painting colors green RAL6010 PRONAR

-

Optional equipment - PT512

Type of drawbar hitch: rigid with Ø40mm eyeType of drawbar hitch: rigid ball K80“Ściany: z wysokiej jakości, mocnych, spawanych laserowo profili PF800mm, wykonanych z profilowanych blach; ze stabilnymi słupkami tylnymi; z odkuwanymi zawiasami (tylko do linek spinających)”Extensions : made of high quality, strong, laser-welded PF800mm profiles, made of profiled sheets; with stable rear posts; with forged locksExtensions : made of high quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged locksSlats / tie-down cords for walls / extensions - choice at ordering stageCenter extensions : made of high quality, strong, laser-welded PF600mm profiles, made of profiled sheets; with stable rear posts; with forged locksHydraulic brake systemHydraulic brake system with electric safety valve and three-range brake force regulatorTwo-wire air brake system with automatic (ALB) brake force regulator (with rear output)Air brake system "Premium" two-wire with automatic (ALB) brake force regulator (with output to the rear)BalconyGutter for the chute shaftSprings to assist the opening of the side wallsPlastic fenders (additional) - in front of the front wheelSide protection (guards )Manual rear hitch MH 31H-4Automatic rear hitch AH 31H-4Triangle to distinguish slow-moving vehiclesDeposited chute left or right over the entire length of the trailer bedFolding chute left + right over the entire length of the trailer bedWindow in the front extension (340×710 ) with grille and PLEXII glassWindow in front extension and front center extension (340×710 )with grille and PLEXI glassTwo grain chute shafts, with interlock, in the rear wallThree grain chute shafts, with interlock, in the rear wallRoller tarpaulin with frame with folding center tube and side support tubesPotato drop shock absorber in the form of suspended rubber belts - 2 sets of 1.8m long each mounted to the extensions (need to equip the trailer with extensions)Rear chute on the full width of the trailer

- Download

Are you interested?

Contact our salesperson

We are ready to help you! Enter your postcode and we will indicate the salesperson responsible for your area.

Find our branches

Check out the financing options

We offer a full range of services related to current repairs, diagnostics and inspections of agricultural machinery. We provide service for both individual and business customers.